New Energy, Coal Replacement, Wood Pellet Production Line for Biomass

Description

Basic Info

| Warranty | 2 Years |

| Customized | Non-Customized |

| Condition | New |

| Color | Multi Color |

| After-sales Service | 7*24h Online Service |

| Application | Wood Biomass |

| Transport Package | Standard Packing. |

| Specification | 450 560 580 680 850 880 |

| Trademark | SeitoTech |

| Origin | China |

| HS Code | 84659600 |

| Production Capacity | 100 Sets /Month |

Product Description

Product Description

Sawdust pellet mill, also called sawdust forming machine, is a pellet fuel forming machine with corn straw, straw, wood bran, wood flour, wood chips and other agricultural waste as raw material. The pellets made by sawdust pellet mill can be used in fireplaces, boilers, gasifiers and biomass power plants. The sawdust pellet mill produced by our company is a new generation of biomass pellet making machine, which solves the problem of difficult to press, difficult to bond and difficult to shape the coarse fiber of biomass, with high efficiency, low energy consumption, continuous 24-hour non-stop production, which can be widely used in feed mills, wood processing plants, fuel plants, etc. It is the ideal equipment with small investment, quick effect and no risk.

Working principleBiomass pellet machine host drive adopts high-precision gear drive, ring die adopts fast discharge

The drive of the whole machine is made of high quality bearings from Switzerland and Japan, the ring die is made of fast discharging type, the feeding is made of frequency conversion to ensure even feeding, and the door cover is equipped with strong feeder. With novel structure, compact, safe, low noise, low failure performance.

Detailed Photos

Performance characteristics

1,Vertical feeding, directly in place;

2,The die is stationary, the pressure wheel is rotating, the material is centrifugal and evenly distributed around;

3, two layers of grinding tools, the upper and lower two uses, reduce costs, increase efficiency, and can be dual-use, high production and energy saving;

4, a grinding tool, aperture two, pressing different specifications of the product;

5,Large hole mold, round pipe wire connection, increase the stroke, increase the density;

6,Ring-shaped die, vertical structure, conducive to the granulation chamber heat dissipation and temperature reduction;

7,Independent frequency conversion discharge device, to ensure the pellet molding rate;

8,Independent lubrication system, can realize automatic lubrication without stopping.

Product Parameters

| Model | Power | Pellet size (mm) | Die Dia (mm) | Capacity(t/h) | Dimension (mm) | Weight (T) |

| 450 | 55 | 4-12 | 450 | 0.3-1 | 2200x900x1600 | 3 |

| 550 | 75 | 4-12 | 550 | 0.7-1 | 2300x1000x2300 | 4.8 |

| 560 | 90 | 4-12 | 560 | 1-1.5 | 2600x1300x2300 | 5.8 |

| 580 | 160 | 4-12 | 580 | 1.5-2 | 2900x1300x2400 | 6.5 |

| 680 | 160 | 4-12 | 680 | 2-2.5 | 3200x1400x2400 | 8.5 |

| 850 | 220 | 4-12 | 850 | 2-3 | 3750x1650x3250 | 12.6 |

| 880 | 315 | 4-12 | 880 | 3-4 | 4300x1900x3600 | 14.5 |

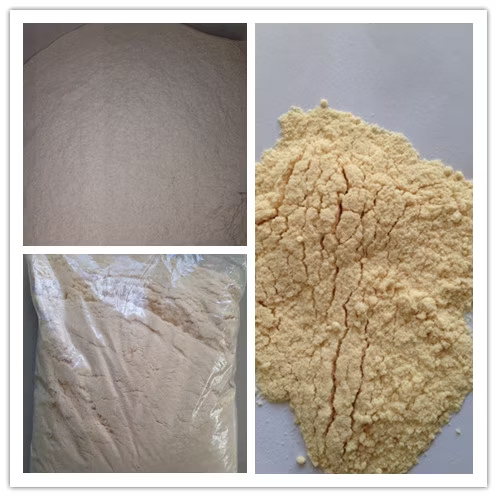

Product pictures show

Application scope: disulfide charcoal plant, mosquito plant, explosives plant, copper processing plant, foundry plant

Applicable materials: eucalyptus, pine, birch, poplar, fruit wood and crop straw, bamboo chips

Feed size: depending on the process

FAQ

1. How will payment be made to you?a. T/T,30% deposit as advanced payment, the balance paid before delivery. b. 30% deposit T/T, balance irrevocable letter of credit at sight.

2, How long is the delivery time?

For standard machines, it takes 3-7 days; For non-standard machines and machines customized according to customer's specific requirements, it wil be 7-10 days.

3, Do you arrange the delivery of machines?

Yes, for FOB or CIF price, we will arrange the shipment for you. For EXW price, customers need to arrange the shipment by themselves or their agents.

4, What is the documentation after shipment?

After shipment, we will send you all original documents via DHL or FedEx, including a packing list, commercial invoice, bill of lading, and other certificates requested by the customer.

5, How about the packaging?

Waterproof plastic film packaging with foam protection at every corner

Solid seaworthy wooden crates with steel straps

Save container loading space as much as possible.6. Are you a factory or trading company?We are a real factory, We can provide online video factory inspection service.7.Do you export by yourself or through an agency?We have the right to self-export and have professional practitioners to follow up the relevant process. Let you worry-free all the way.

Prev: Farm Machinery Livestock Poultry Animal Feed Pellet Mill Plant

Next: Favourable Price Small Livestock Feed Pellet Mill Plant for Chicken Feeding

Our Contact