Factory Price High Output Vertical Ring Die Biomass Pellet Production Line

Description

Basic Info

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Color | Multi Color |

| After-sales Service | 1 Years |

| Pellet Mill Type | Ring Die |

| Application | Making Pellets |

| Product Name | Biomass Pellet Production Line |

| Pellet Formation Rate | Over 98% |

| Size of Wood Pellets | 4/6/8/10/12mm |

| Length of Wood Pellets | Adjustable |

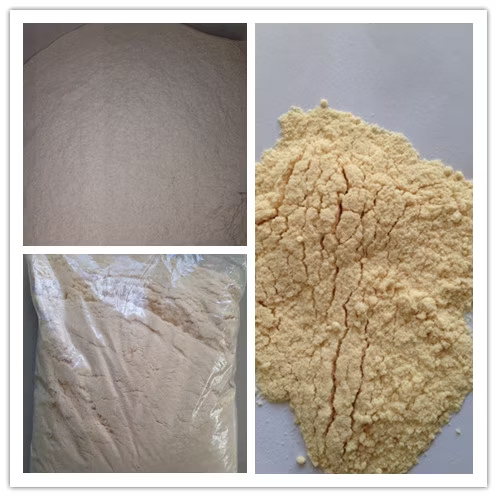

| Materiall for Making Wood Pellets | Sawdust, Rice Husk, Log,Branch, Straw |

| Spare Parts of Wood Pellet Machine | Ring Die and Roller |

| Colour | Client Requirement |

| Key Words | Biomass Pellet Production Line |

| After-Sales Service Provided | 24 Hours Online Service |

| Service | OEM ODM |

| Quality | Top Level |

| Transport Package | Wooden Box, Iron Frame |

| Specification | 1-4t/h |

| Trademark | zhangsheng |

| Origin | China |

| HS Code | 8465960000 |

| Production Capacity | 300sets/Month |

Product Description

Waste wood pellet production line integrates all processes from raw materials to pellets, including crushing, drying, pellet making, cooling and packing, with an output of 1 to 10 tons per hour. It can process various waste wood, such as planks, wood chips, tree branches, tree trunks, building templates, etc. Wood pellets have high calorific value, low cost, small size, easy transportation and no pollution. With the increasing shortage of coal, oil and other energy sources, the market demand for wood pellets is increasing, and the profits are considerable.

A lucrative project - biomass pellets production

Why Choose US

Process Flow

Case show

Experience of manufacturing and installing project globally, which help them get huge economic benefits.

Company Profile

Certifications

As a professional exporter of wood pellet machine production lines, Zhangsheng has exported to more than 45 countries. We have the whole production line manufacturing capacity of crushing, crushing, drying, granulating, cooling, packaging, etc. Deeply cultivated in the field of wood recycling, all wood pellet machines are CE certified by TUV-SUD and TUV-Rheinland. The total number of wood pellet machine projects exported to Europe and North America exceeds 100 sets each year.Prev: Homemade Extruder Pelletizer Machine Pig Animal Feed Granule Mill Pellet Machine

Next: China Brand Construction Equipment Hydraulic Crushing Pliers

Our Contact