Complete Wood Biomass Fuel Pellet Making Machine Production Line

Description

Basic Info

| Model NO. | JTKL |

| Type | Flat Die Platen Wheel |

| Voltage | as Clients′s Requirement to Customize |

| Automatic Grade | Automatic |

| Controlling Mode | CNC |

| Energy Saving | Energy Saving |

| Certification | CE, ISO |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Color | Customized |

| Capacity | 0.8-5.0t/H |

| Power | 135-300kw |

| Weight | 45-73t |

| Area | 10m*24m-12m*26m |

| Application | Sawdust, Bamboo Shavings, Wood Shavings, etc. |

| Transport Package | Plywood Box/Plastic Woven Clothes |

| Origin | Henan, China |

| Production Capacity | 500 Sets/Year |

Product Description

Biomass Pellet Production Line

Product Description

Biomass pellets are an economical and sustainable energy source, which is being used more and more globally due to its low cost and low environmental impact.

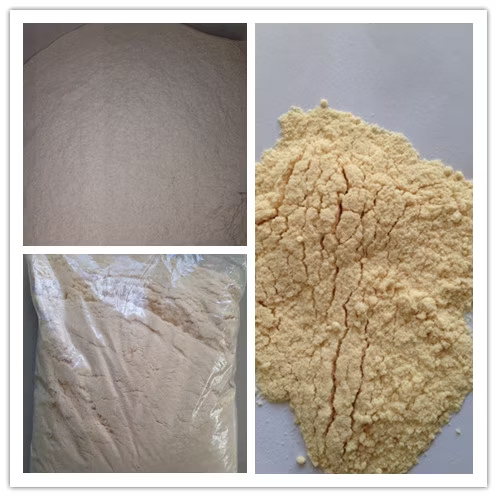

According to the demand of the market, our technical team designs and manufactures the equipment of biomass pellet production line, which are suitable for the biomass material with the 35-56% moisture to make pellet, such as sawdust, bamboo shavings, wood shavings, barley straw, oat straw, wheat straw, rye straw, rice straw, rice husk, bagasse, sorghum straw, corn straw, beans stalk, peanut vine stalk, etc. From crushing, drying, granulating to cooling, and packaging, Jiutian provides both a separate machine and a complete production line. Provide raw materials and capacity requirements, we can provide you with detailed solutions and special granulation equipment.

Working Principle

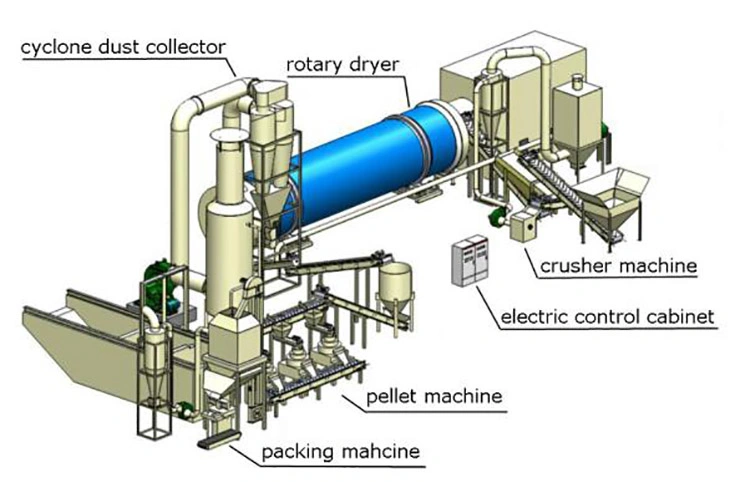

The pellet machine using the die roll extrusion principle, the agriculture residues biomass raw materials processed into solid molding fuel, this will realize to continuous and stable production of industrialization. The processing route uses one-time drying, secondary crushing, continuous feeding and adjust feeding mixed process combining, the Particle shaping fuel rate of 98%, bulk density, and particle density is high.

Production Process

Raw Materials PreparationWood pellets can be made from sawdust, wood shavings, wood chips or wood logs, any forestry waste or straws, etc.Crushing ProcessCrushing machine is used for crushing the larger materials into smaller powder for supporting produce wood pellets. After milled, the output size can reach a diameter of 3-5mm, which is convenient for further processing to get dried and pelletized.Drying ProcessThe best moisture content for pelletizing is about 11-17%. So before pelletizing, a drying machine is needed to make the moisture content reaches the required standards.Wood Pelletizing ProcessPellet mill is a significant part of the wood pellet production line and has reliable and stable performance. You can choose a ring die pellet mill or flat die pellet mill depends on your capacity requirements.Cooling ProcessAfter the pelletizing process, the temperature of wood pellets is between 60-80 degrees and the moisture content is close to 15%. So a cooler must be used to reduce their surface temperature and the moisture content which makes the wood pellet easy to store meanwhile helps screen good and pure pellets.Packing ProcessAfter the cooling process, the packing process is necessary to protect the wood pellets from the damp. The automatic wood pellet weighing & packing system adopts PLC control with high weighing accuracy and easy operation.

Applications

Product Features

1. Patent technology (patent no. : ZL200920089749.2), single equipment the kinds are variety, application to a variety of materials, modular structures, optimize configurations, ensure production lines broad applicability.2. According to customer's requirements to realize intelligent control, a key "fool" type operation.3. More than 300 users in the world, our factory has rich practical experience.4. The cover area reduces 50% than the traditional drying granulating production line, civil investment reduces about 50%.5. Waste gas discharge temperature is lower than 50 ºC, low energy consumption.6. Particle shaping fuel rate of 98%, bulk density, and high density.7. Special design ash control technology, ash content lower than 1%.8. Modular dust collecting and purifying heat recycling configuration, safe and protect environmentally.9. This type of mixing drum dryer is supporting many new types of energy-saving hot air stove, energy consumption drops about 30%, power consumption reduces 20%, lower operation costs.10. Internet sharing systems can ensure that personalized production lines, accessories, and unit efficient distributions in place.

Product Parameters

We can help optimize the drying process according to the property of different materials, production scale, application requirements, cost control, automation level, and site condition.

| Model | Capacity(t/h) | Motor power(kW) | Weight(ton) | Area(m²) |

|---|---|---|---|---|

| JTKL1000 | 0.8-1.0 | 135 | 45 | 10×24m |

| JTKL1500 | 1.2-1.5 | 175 | 47 | 10×24m |

| JTKL2000 | 1.5-2.0 | 210 | 55 | 10×24m |

| JTKL3000 | 2.5-3.0 | 255 | 68 | 12×26m |

| JTKL5000 | 4.5-5.0 | 300 | 73 | 12×26m |

Company Profile

Jiutian Machinery has made constant innovations in the biomass pellets production industry and accumulated a wealth of experience in tackling the various challenges facing wood pellets companies, more importantly, is able to offer a range of comprehensive solutions. Now we have evolved into one of China's famous manufacturers of wood pellet production lines with over 100 staff.Till now, we have successfully constructed more than 100 pellets production turnkey projects around the world, covering raw material as sawdust(Morocco, Vietnam, Bulgaria), logs(Romania), wood(Malaysia), wood shaving(Tunisia), and also many projects in China, like in Hunan, Jiangsu, etc.

Prev: Wood, Straw, Wood Pellet Mill Stalk, Biomass Pellet Production Line

Next: Poultry Farm Machinery Feed Mill Extruder Animal Pellet Machine

Our Contact