2023 New Design Wood Sawdust Pellet Making Machine Biomass Wood Pellet Machine

Description

Basic Info

| Model NO. | 450 560 580 680 850 880 |

| Type | Flat Die Cone Wheel |

| Voltage | 380V |

| Automatic Grade | Automatic |

| Controlling Mode | CNC |

| Energy Saving | Energy Saving |

| Certification | CE, ISO |

| Warranty | 2 Years |

| Customized | Non-Customized |

| Condition | New |

| Color | White or Customized |

| After-sales Service | 7*24h Online Service |

| Capacity | 0.4-0.7t/H |

| Motor | 55kw |

| Product Size | 4-12 |

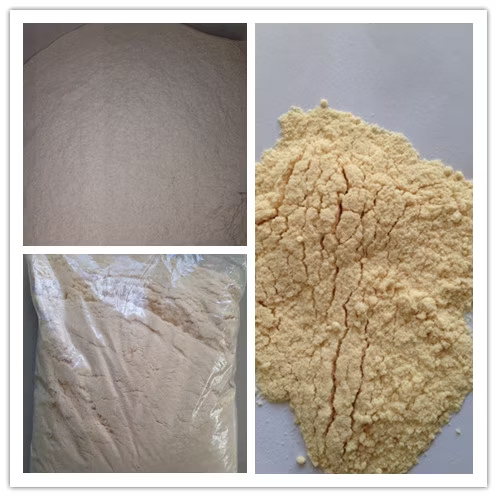

| Material | Corn,Straw, Wood Bran, Wood Flour, Wood Chipper |

| Factory | Yes. Allow Factory Inspection with Video |

| Advantages | Factory Direct Sale. Fast Delivery. Good Service. |

| Delivery | Normally 3-5 Days |

| Technicians | 3 |

| Factory Area | 5000m2 |

| Packing | with Plastic Film, or Wooden Cases |

| Application Material | Sawdust, Biomass, Branches etc |

| Keyword | Wood Pellet Mill |

| Structure | Ring Die Pressing |

| Usage | Biomass, Feed etc |

| Product Line | Crusher-Dryer-Pellet Machine-Packing Machine |

| Transport Package | Standard Packing. |

| Specification | 450 560 580 680 850 880 |

| Trademark | SeitoTech |

| Origin | China |

| Production Capacity | 500 Sets /Month |

Product Description

A wood pellet machine, also known as a wood pellet mill, is a type of equipment used to convert wood waste, such as sawdust, wood shavings, wood chips, and other types of wood residue, into wood pellets. Wood pellets are cylindrical, dense, and compacted fuel units that are used in wood pellet stoves, boilers, and other heating systems.

The wood pellet machine works by compressing wood waste under high pressure and temperature, which causes the lignin in the wood to soften and bind the wood particles together. The resulting wood pellets are uniform in size and shape, have a high energy density, and are easy to handle and transport.

Wood pellet machines come in different sizes and capacities, ranging from small home-use machines to large industrial-scale machines that can produce thousands of tons of wood pellets per year. They are used by wood pellet manufacturers, wood product manufacturers, farmers, and individuals who generate wood waste and want to turn it into a valuable fuel source.

The working principle of a wood pellet machine involves several steps:Raw Material Preparation: Wood waste such as sawdust, wood chips, or wood shavings are collected and prepared for the pelletization process. The raw material is usually screened to remove impurities, and then ground to a uniform size suitable for pelletization.

Feeding: The prepared raw material is fed into the wood pellet machine through a hopper, which directs the material into the pelletizing chamber.

Pelletizing: Inside the pelletizing chamber, the raw material is compressed under high pressure and temperature. The compression process softens the lignin in the wood, which acts as a natural binder to hold the wood particles together. The heat generated by the compression process also helps to melt and bind the wood fibers together.

Shaping: The compressed material is forced through a die, which shapes the material into uniform cylindrical pellets. The size of the die determines the size of the pellets produced.

Cooling and Drying: The newly formed pellets are hot and soft, so they need to be cooled and dried to harden them and remove any remaining moisture. The pellets are typically cooled using a pellet cooler and then dried using a pellet dryer.

Packaging: Once the pellets have been cooled and dried, they are ready for packaging. The pellets can be packaged in bags or stored in bulk for transport and sale.

The working principle of a wood pellet machine involves compressing wood waste under high pressure and temperature, shaping the compressed material into pellets, and then cooling and drying the pellets to produce a high-quality fuel source.

Detailed Photos

Wood pellet machines are designed to efficiently and effectively convert wood waste into high-quality fuel pellets. Here are some of the key performance characteristics of a wood pellet machine:

High Pellet Production Efficiency: A good wood pellet machine should have a high production capacity, which means it can produce a large quantity of pellets in a relatively short amount of time. This efficiency is achieved through the use of powerful motors, high-quality dies, and optimized pelletizing processes.Consistent Pellet Quality: The consistency and quality of the pellets produced by the machine are important factors that determine the performance of the machine. The pellets should be uniform in size, shape, and density, with low levels of fines and other impurities. This ensures that the pellets can be easily transported, stored, and used in various heating systems.Low Energy Consumption: A high-quality wood pellet machine should have a low energy consumption per unit of output. This means that it should be energy-efficient and consume less power to produce the same amount of pellets. This not only reduces the cost of production but also helps to minimize the carbon footprint of the machine.Easy Maintenance: A good wood pellet machine should be easy to maintain and operate. It should have simple and intuitive controls, easy-to-replace parts, and a durable and reliable design. Regular maintenance and cleaning of the machine can also help to extend its lifespan and ensure optimal performance.Flexibility in Raw Material Processing: A high-quality wood pellet machine should be able to process a variety of raw materials, including different types of wood waste, agricultural waste, and other biomass materials. This allows the machine to be used in various industries and applications, such as heating, animal feed production, and biomass energy generation.The performance characteristics of a wood pellet machine are critical factors that determine its efficiency, reliability, and cost-effectiveness. A well-designed and high-quality machine can produce high-quality pellets that meet the needs of various applications and industries.

Product Parameters

| Model | Power | Pellet size (mm) | Die Dia (mm) | Capacity(t/h) | Dimension (mm) | Weight (T) |

| 450 | 55 | 4-12 | 450 | 0.3-1 | 2200x900x1600 | 3 |

| 550 | 75 | 4-12 | 550 | 0.7-1 | 2300x1000x2300 | 4.8 |

| 560 | 90 | 4-12 | 560 | 1-1.5 | 2600x1300x2300 | 5.8 |

| 580 | 160 | 4-12 | 580 | 1.5-2 | 2900x1300x2400 | 6.5 |

| 680 | 160 | 4-12 | 680 | 2-2.5 | 3200x1400x2400 | 8.5 |

| 850 | 220 | 4-12 | 850 | 2-3 | 3750x1650x3250 | 12.6 |

| 880 | 315 | 4-12 | 880 | 3-4 | 4300x1900x3600 | 14.5 |

Product pictures show

A wood pellet machine can be used to process a variety of materials, including:

Wood Waste: The most common application for a wood pellet machine is to process wood waste, such as sawdust, wood chips, and wood shavings. These materials are readily available and are typically generated as byproducts in the woodworking industry.

Agricultural Waste: The machine can also be used to process agricultural waste, such as straw, corn stalks, and other crop residues. These materials are abundant and can be a valuable source of biomass for pellet production.

Other Biomass Materials: In addition to wood and agricultural waste, a wood pellet machine can process other types of biomass materials, such as grass, leaves, and other plant matter.

Biomass Energy Crops: Dedicated energy crops, such as switchgrass and miscanthus, can also be used as feedstock for pellet production.

Industrial Waste: Some types of industrial waste, such as paper and cardboard, can be processed using a wood pellet machine to produce fuel pellets.

A wood pellet machine can be used to process a wide range of materials, making it a versatile tool for biomass energy production and waste reduction. The choice of material depends on factors such as availability, cost, and the specific requirements of the application.

FAQ

1. How will payment be made to you?a. T/T,30% deposit as advanced payment, the balance paid before delivery. b. 30% deposit T/T, balance irrevocable letter of credit at sight.

2, How long is the delivery time?

For standard machines, it takes 3-7 days; For non-standard machines and machines customized according to customer's specific requirements, it wil be 7-10 days.

3, Do you arrange the delivery of machines?

Yes, for FOB or CIF price, we will arrange the shipment for you. For EXW price, customers need to arrange the shipment by themselves or their agents.

4, What is the documentation after shipment?

After shipment, we will send you all original documents via DHL or FedEx, including a packing list, commercial invoice, bill of lading, and other certificates requested by the customer.

5, How about the packaging?

Waterproof plastic film packaging with foam protection at every corner

Solid seaworthy wooden crates with steel straps

Save container loading space as much as possible.6. Are you a factory or trading company?We are a real factory, We can provide online video factory inspection service.7.Do you export by yourself or through an agency?We have the right to self-export and have professional practitioners to follow up the relevant process. Let you worry-free all the way.

Our Contact