2021hotsale Industrial Complete Customized Big Straw Rice Husk Biomass Sawdust Wood Pellet Plant for Large Scale Wooden Log Chips Fuel Pelletizing Production

Package size per unit product 1.00cm * 1.00cm * 1.00cm Gross weight per unit product 10000.000kg ✠ Turnkey Project Plan

Description

Basic Info

| Model NO. | WVPML 5-6 |

| Controlling Mode | Artificial |

| Energy Saving | Energy Saving |

| Certification | CE, ISO, FDA |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Color | Multi Color |

| Name | Wood Pellet Making Machine |

| Material | Stainless |

| Raw Material | Wood, Sawdust, Biomass, Rice Husk |

| Motor | Chinese Brand |

| Usage | Making Biomass Pellets, Sawdust Pellets |

| After-Sales Service Provided | Online Support |

| Certifications | CE ISO SGS |

| Model | Ring Die Wood Pellet Making Machine |

| Application | Automatic |

| Weight | Customized |

| Trademark | ABC Machinery |

| Origin | China |

Packaging & Delivery

Package size per unit product 1.00cm * 1.00cm * 1.00cm Gross weight per unit product 10000.000kgProduct Description

✠ Turnkey Project Plan for sawudst biomass wood pellet making machine ✠

| ▸Product Details of wood pellet making machine |

One of our wood pellet making machine project has finished construction. It is a 2~3 ton per hour complete production line for making biofuel pellets from chestnut wood, including process of crushing, drying, pelletizing, cooling and packing. PLC system is also included in the pellet plant. (Related Project: Wood Pellet Production Line in UK)

▮ Pellet Plant Under Constructing

| Type | Capacity (t/h) | Power (kw) | Pellet Size | Pellet Type | Scope of Materials |

| BPM420 | 1-1.5 | 90 | 6/8/10/12 | Biomass wood pellets, Animall feed pellets. | Wood waste, agriculrure waste, Waste paper, Tree Sawdust, Wheat, Straw, Rice Husk, Cocunut, Peanut, Shells, Sunflower Seeds, Palm Leaf, Bagasse, Alfalfa and others. |

| BPM508 | 1.5-2 | 110/132 | |||

| BPM510 | 1.5-1.8 | 90/110 | |||

| VPM510 | 1-1.5 | 110 | |||

| VPM630 | 1.5-2 | 132 | |||

| VPM660 | 2-3 | 165 |

As a result of the current economic changes there is an elevated quest to seek alternative sources of energy in order to save on expenses and conserve the environment. In this case, wood pellets are considered as one of the most common type of fuel compared to gas, oil and coal just a few but to mention. This has motivated a number of entrepreneurs to start their own pelleting projects. However, most of the entrepreneurs face challenges of using their own expenses. This triggers the question: How much it could cost to build wooden pellet plant.

Contact Now for Catalogs & Best Price!

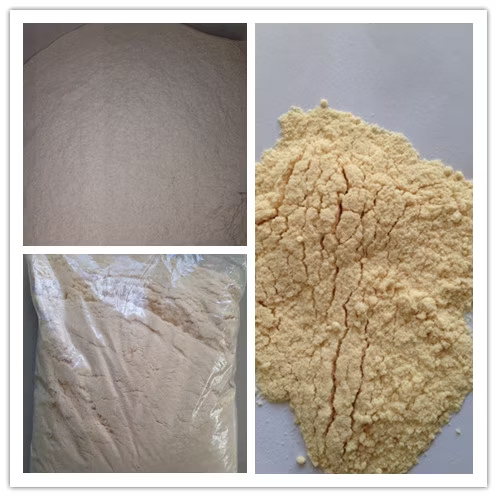

| ▸Raw Material of wood pellet making machine |

Biomass Wood Pellet Machine also called sawdust pellet making machine, pellet granulator, fodder pellet mill, briquette pelletizing machine (machine de fabrication de la paille, pelletizadores, peletizadora pellet). The flat die has only vertical type, while the ring die (Circular Mould Ring Matrice - 2 layers matrix) have vertical and horizontal structure, it is not hot press machine, but cold press machine. The automatic multipurpose pellet machine production factory is a complete plant project which can processing large range of materials and producing (manufacturing) biofuel pellets. High capacity manufactures are making pellets for power plant, home use, industry use.Scope of Materials:Wood waste, agriculrure waste, Waste paper, Tree Sawdust, Wheat, Straw, Rice Husk, Cocunut, Peanut, Shells, Sunflower Seeds, Palm Leaf, Bagasse, Alfalfa and others.Common trees for Our Biomass Pellet Making Machine: Teak, Mangrove, Maple, Sycamore Maple, Spruce, Cryptomeria Plum, Mahogany Eucalyptus, Ficus cedar, European Beech, European Olive, Aleppo Pine, Cork English Oak, Small-leaved Lime…

Contact Now for Catalogs & Best Price!

| ▸Part of the wood pellet making machine |

Contact Now for Catalogs & Best Price!

| ▸How to make pellet by biomas pellet making machine |

1. Use Wood Chipper, Wood Crusher to make wood logs, chips (or other materials) smaller.

2. Use Dryer (rotary drum dryer / Air-flow dryer) or add water to the sawdust(or other materials) till its moisture content between 8-15%, which is the best moisture content for pelletizing.

3. Put the sawdust into the pellet machine gradually. Large scale pellet production need a screw feeder to make sure stable feeding of raw material.

4. After pelletized, the pellets are of high temperature that is not suitable for direct packing. So they should be cooled by pellet cooler.

Then, pellets go through a vibrating sieve, where good pellets will be left, while broken ones or powder will be collected for reproduction.

5. After all the above procedures, pellets can be packed with a pellet packing machine. Contact Now for Catalogs & Best Price!

| ▸Advantages of sawdust pellet making machine |

★ It is a large pellet mill. So it is mostly used in industrial pellet production.

★ The pellet mill is especially suitable for processing wood and palm fiber. So many investors with large quantity of wood or palm fiber material choose ring die pellet mill instead of flat die pellet mill.

★ A set of ring die pellet mill has relatively longer service life compared to flat die pellet mill.

★The pellets made by ring die pellet mill have larger density and smoother surface since ring die pellet mill has higher pressure. If you want to produce pellets in large scale, ring die pellet mill is your best choice.

Contact Now for Catalogs & Best Price!

| ▸Installation of biomas pellet making machine |

| ▸Why Choose ABC Machinery for sawdust pellet making machine |

Our Contact

Send now